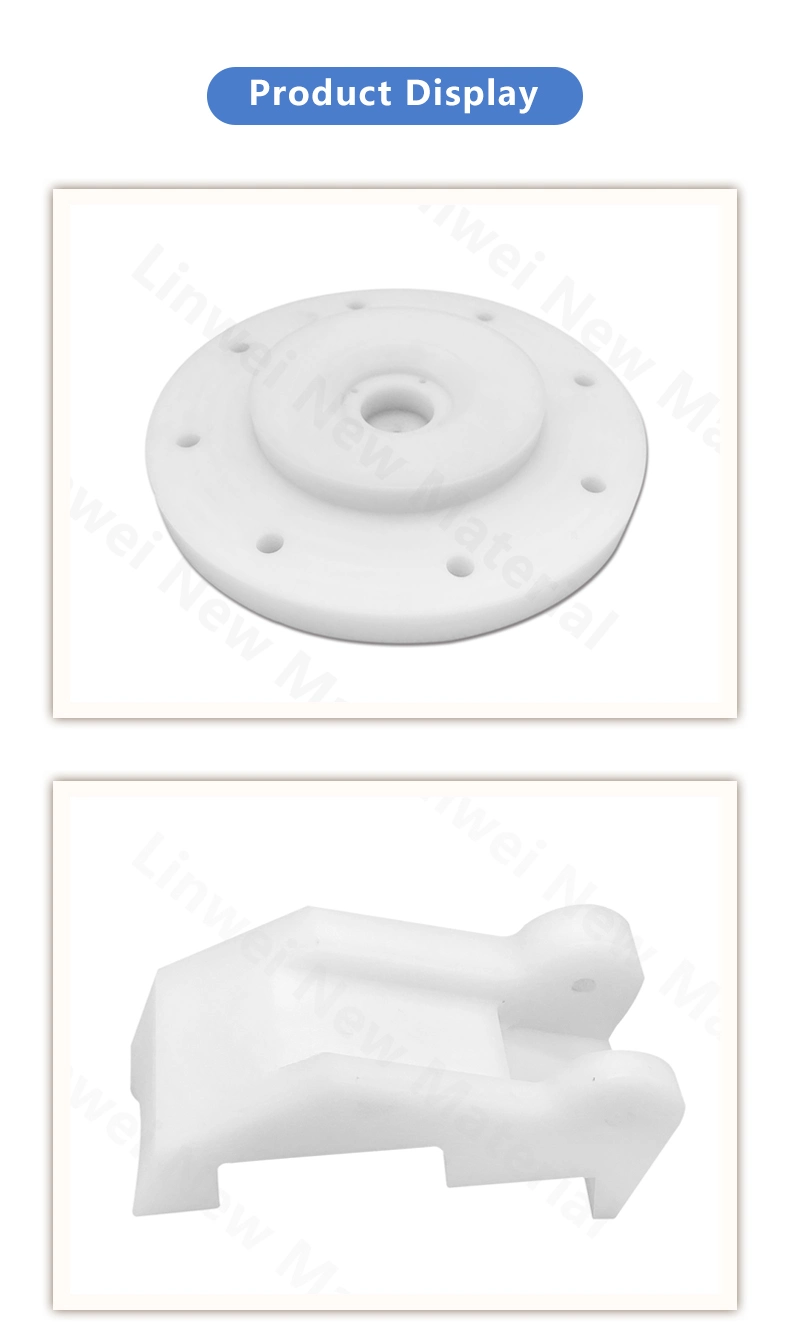

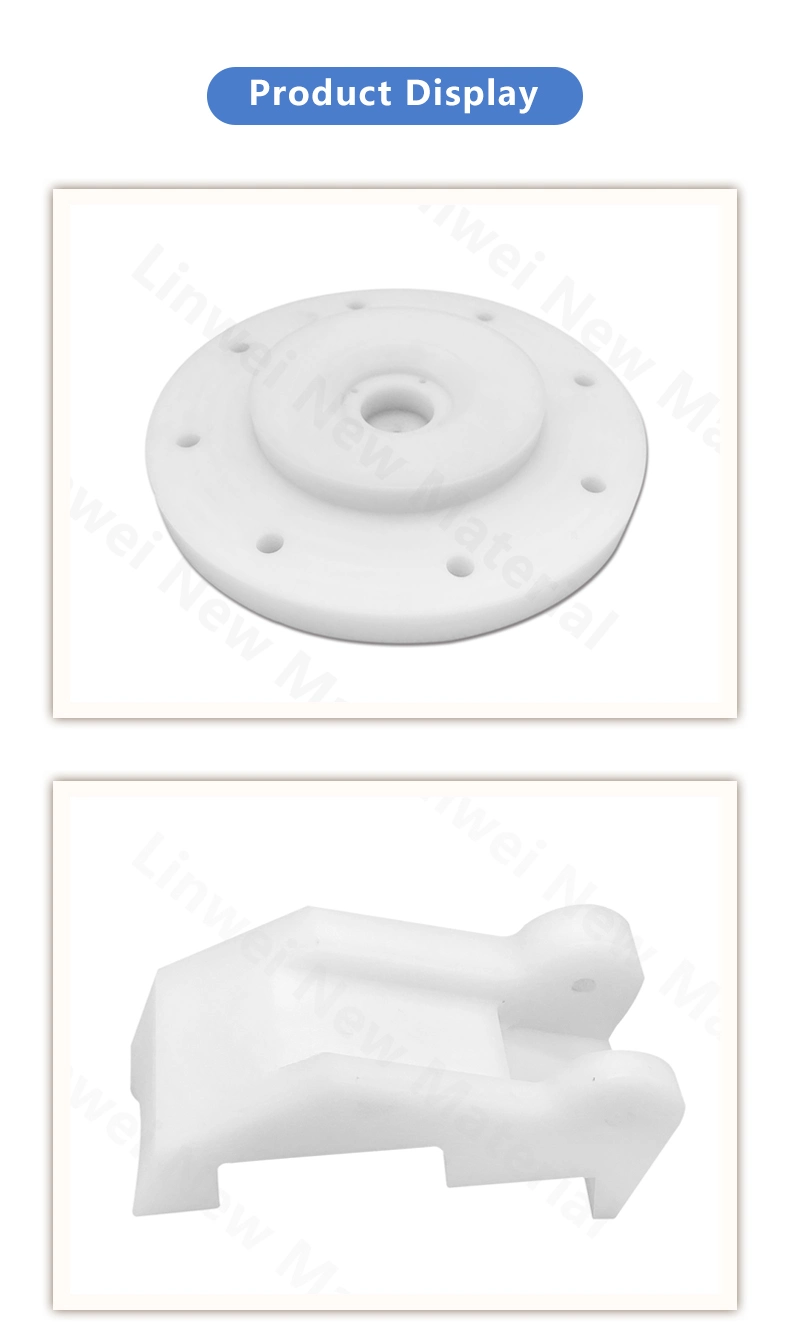

Product Description:

UHMW PE is the abbreviation of English Ultra High Molecular Weight Polyethylene (ultra-high molecular weight polyethylene). This is the highest quality polyethylene available in harsh working environments and for multiple purposes. The applicability is very good in many difficult application conditions. Ultra-high molecular weight is the distinctive feature of this polymer, which has a molecular weight of 3 to 6 million, while high-density polyethylene resin is only 300,000 to 500,000. This difference is to ensure that the UHMWPE has sufficient strength to achieve the wear resistance and impact resistance that other low-grade polymer products cannot have. The meaning of the ultra-high molecular weight of UHMWPE is that it will not melt and flow like a liquid, so the processing method is derived from powder metal technology. Traditional plastic processing techniques, such as injection molding, blow molding, and heat setting, cannot be applied to UHMWPE. Extrusion molding is the most common processing technology applied to this resin, so that the product produced is more tough. Ultra-high molecular weight polyethylene refers to a linear structure polyethylene with a molecular weight of more than 3 million. It is an engineering plastic with the best comprehensive performance. Its wear resistance, impact resistance, corrosion resistance, self-lubricating, and impact energy absorption-these five properties are the current There are the best plastics, which are called "amazing materials" internationally.

Product Performance:

Mechanical Behavior

Note: The above parameters are for reference only. The actual data is based on the product test data.

Thermal Performance

Note: The above parameters are for reference only. The actual data is based on the product test data.

Our Service

1. Providing technical consultation.

2. Samples are free.

3.We could customize various products with your brand logo according to your requirements.

4. Your inquiry will be replied within 1 hours during working time,Within 24 hours when rest time.

5.Orders will be produced exactly as request and approved samples.

6. Before shipment,our QC will have inspection to make sure the quality.

7.We always try best to ensure every order to delivery in time.

8.Special packaging according to request.

UHMW PE is the abbreviation of English Ultra High Molecular Weight Polyethylene (ultra-high molecular weight polyethylene). This is the highest quality polyethylene available in harsh working environments and for multiple purposes. The applicability is very good in many difficult application conditions. Ultra-high molecular weight is the distinctive feature of this polymer, which has a molecular weight of 3 to 6 million, while high-density polyethylene resin is only 300,000 to 500,000. This difference is to ensure that the UHMWPE has sufficient strength to achieve the wear resistance and impact resistance that other low-grade polymer products cannot have. The meaning of the ultra-high molecular weight of UHMWPE is that it will not melt and flow like a liquid, so the processing method is derived from powder metal technology. Traditional plastic processing techniques, such as injection molding, blow molding, and heat setting, cannot be applied to UHMWPE. Extrusion molding is the most common processing technology applied to this resin, so that the product produced is more tough. Ultra-high molecular weight polyethylene refers to a linear structure polyethylene with a molecular weight of more than 3 million. It is an engineering plastic with the best comprehensive performance. Its wear resistance, impact resistance, corrosion resistance, self-lubricating, and impact energy absorption-these five properties are the current There are the best plastics, which are called "amazing materials" internationally.

Product Performance:

Mechanical Behavior

| Indicator Name | Unit | Testing Method | Index |

| Density | g/cm3 | ASTM1505 | 0.94 |

| Breaking Strength | Mpa | D638 | 42 |

| Elongation At Break | % | D638 | 350 |

Thermal Performance

| Indicator Name | Unit | Testing Method | Index |

| Melting point | ºC | ASTMD2117 | 136 |

| Vicat softening point | ºC | ASTMD1512 | 134 |

| Thermal expansion coefficient | 10-4/ºC | ASTMD648 | 1.5 |

Our Service

1. Providing technical consultation.

2. Samples are free.

3.We could customize various products with your brand logo according to your requirements.

4. Your inquiry will be replied within 1 hours during working time,Within 24 hours when rest time.

5.Orders will be produced exactly as request and approved samples.

6. Before shipment,our QC will have inspection to make sure the quality.

7.We always try best to ensure every order to delivery in time.

8.Special packaging according to request.