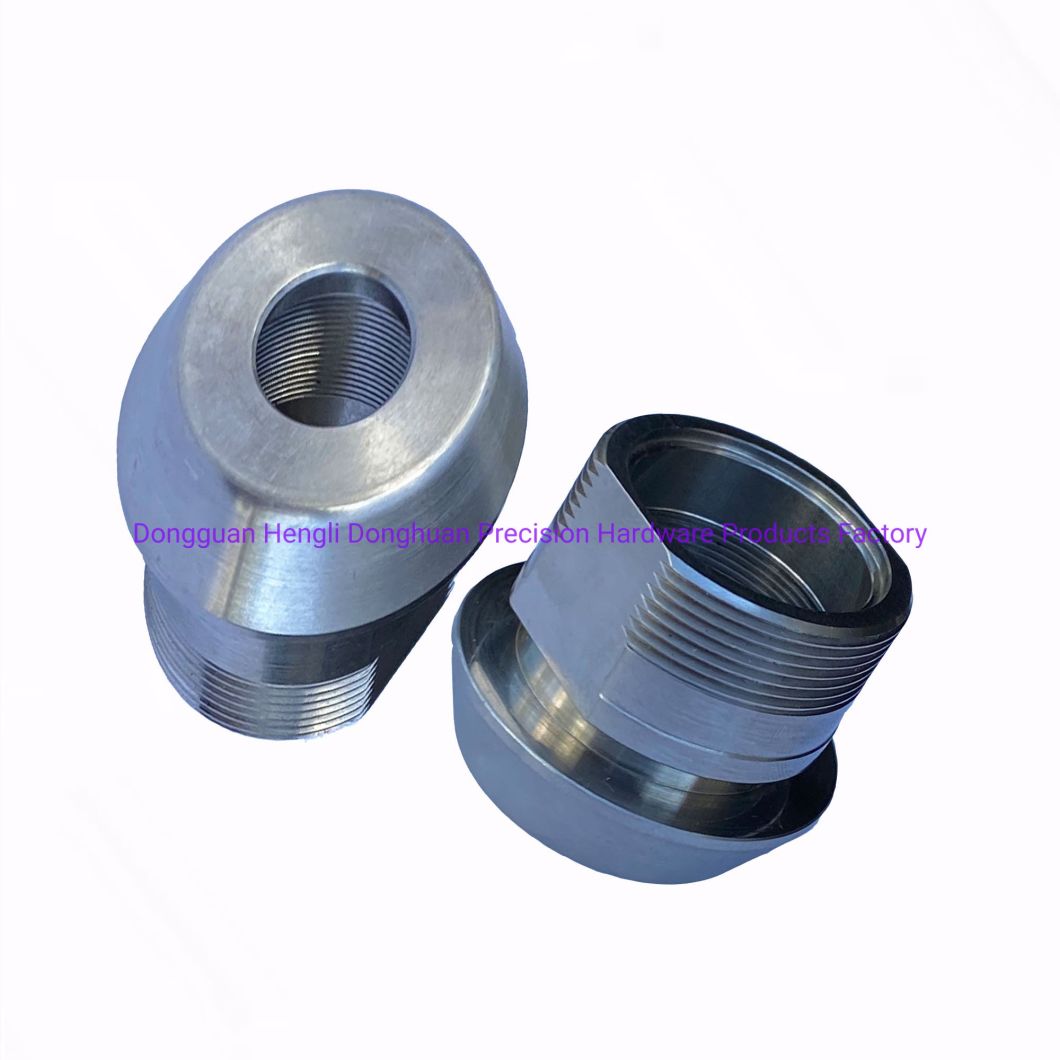

Finishing Turning Parts Processing Stainless Steel Auto Parts

| Processing range | Fasteners/precision hardware machinery parts, communication parts, optoelectronic parts, automobile and motorcycle parts/hardware tools |

| Processing material | Aluminum alloy: AL6061, AL6082, AL5052, AL7075, AL6063, etc |

| Stainless Steel: SUS303/SUS304, SUS316 | |

| Brass: C36000 (C26800), C37700 (Hpb59), C38500 (Hpb58), C27200 (Cuzn37)C28000 (Cuzn40), etc | |

| Steel :45#, A3#,20# etc | |

| Nylon, ABS,POM bar, etc | |

| Iron: 1213, 1214, 1215, etc | |

| Processing equipment | CNC machining center five axis CNC machining center, CNC lathe, CNC milling machine, CNC turning and milling compound, grinding machine, etc |

| The machining accuracy | Machining accuracy +/- 0.005mm |

| Testing equipment | 3 D measuring instrument, spectrum analyzer, height measuring instrument, microscope, Sanfeng caliper, micrometer, etc |

| Product surface treatment | Electroplating: zinc plating, nickel plating, chromium plating, tin plating |

| Sand blasting or anodic oxidation, hard oxidation and so on | |

| Professional packaging | Inner packing foam, PE bag, standard packing/carton or pallet/according to custom specification, no scratch or damage. |

| Service | OEM/ODM services |

| There is any problem with the after-sale service | |

| Our products will meet your requirements | |

| Quality control | 100% complete inspection |

| The time of delivery | Sample normal, 3-5 working days; |

| For mass production, it takes about 12-15 working days. | |

| If there are any urgent parts, we will provide priority machining and control the delivery time according to your request. | |

| Total solution provider | From material procurement, product design and shipping of finished products, |

| Inclusive Supply chain management (ODM/OEM) and other aspects of one-stop solution. | |

| Note | All CNC machining parts are customized according to customers' drawings or samples. There is no inventory. |

| If you have any CNC machining parts to manufacture, please feel free to email us your class drawings/samples. |

EQUIPMENT LIST ---

| Dongguan Donghuan Hardware factory | |||||

| Machine Type No. | Name | Q'TY | System | Size Spec./ Range of Work | Machine Accuracy |

| 1 | CNC lathe | 35 | FANUC/SYNTEC-3 | ∮300*500 (D*L) | 0.004mm |

| 2 | CNC turning & milling lathe | 6 | FANUC/MITSUBISHI | ||

| 3 | CNC machining center | 4 | MITSUBISHI | 600*650*400 | 0.008mm |

| 2 | FANUC | 500*400*200 | 0.005mm | ||

| 4 | Surface grinder | 3 | SYNTEC-3 | 900*400 | 0.005mm |

| 5 | Cylindrical grinder | 1 | ∮200*400 (D*L) | 0.005mm | |

| 6 | Centerless grinder | 1 | ∮200*400 (D*L) | 0.01mm | |

| 7 | Hook shot blasting machine | 2 | |||

| 8 | Ultrasonic Cleaner | 2 | |||

| 9 | Vibration grinder | 1 | |||

| 10 | Vibration grinder | 2 | |||

Related Products

About Us

Dongguan Donghuan Precision Hardware Products Factory is located in Dongguan City, Guangdong Province, China. We have extremely convenient traffic conditions.

Founded in 2015, the company currently covers an area of more than 1,000 square meters and has more than 80 full-time employees. The company is mainly a professional manufacturer of non-standard parts and batch products such as CNC precision hardware parts processing, mechanical parts, hydraulic products, electronic product parts, agricultural machinery parts, auto and motorcycle parts. The company has a sophisticated technical team, advanced processing equipment and quality testing equipment, and adheres to the "customer first" "people-oriented, continuous innovation, high-quality and fast" business policy. We promote the spirit of unity, hard work, pioneering and enterprising. Our company is willing to cooperate sincerely with companies all over the world to achieve a win-win situation.

FAQ:

1. Are you a factory or a trading company?

We are a professional precision hardware accessories factory. The factory is located in Hengli, Dongguan. welcome.

2. How long can I get a quote from your company?

If we receive detailed information about work consultation, we will contact you within two hours.

In order to quote you as soon as possible, please provide us with the following information and your inquiry.

1) Detailed drawings (CAD / PDF / DWG / IGS / STEP / JPG)

2) Required materials

3) Surface treatment

4) Quantity (per order/month/year)

5) Any special requirements: packaging, labeling, delivery, etc.

3. How is the product quality?

Perform 100% inspection during the production process and ensure that the product 100% meets your requirements. If you have any questions during use, please feel free to contact us, we will reply you in time.

4. Can I take samples for testing?

For small parts samples, we provide free samples, and large parts products will charge a sample fee.

5. What are the payment terms?

For new customers, we prefer to use wire transfers in advance, and we can accept letters of credit from old customers.

6. Can we sign a confidentiality agreement?

Of course, we will never disclose any customer information to others. Thank you very much for your reading, and a warm welcome to inquire or visit us. If you have any questions, please feel free to contact us.